In sustainable design, we often talk about performance, that is, thermal, structural, and acoustic. But increasingly, we’re asking our materials to do more. To protect the planet. To reduce maintenance. To contribute to healthier places. That’s where photocatalytic coatings come in.

You might know them for their self-cleaning properties. But that’s just scratching the surface. These coatings are helping buildings actively improve air quality by turning passive facades into climate-positive players in the urban landscape.

At ECOTONE, we believe that the materials we use should serve the environment as well as the architecture. And when you combine photocatalytic technology with long-life colour coatings, you experience the ECOTONE WOW!

What’s a Photocatalytic Coating, Really?

Photocatalytic coatings are water-based finishes that contain titanium dioxide (TiO₂) which is a naturally occurring mineral that reacts with sunlight. When applied to concrete, brick, or mineral-based substrates, it uses UV light to break down airborne pollutants and organic matter like soot, mould, and surface grime. This phenomenon, known as the Honda-Fujishima effect, was first discovered by Dr. Fujishima back in 1967 and remains a key breakthrough in material science.

These coatings can be applied as a top layer over ECOTONE’s long-life colour coatings, adding environmental performance without changing your colour scheme, texture, or finish. They’re transparent, breathable, and designed to disappear visually, but not functionally.

A cleaner surface for longer

Let’s start with the practical side. Photocatalytic coatings significantly reduce surface soiling. They break down airborne grime, making it easier for rain to wash dirt away.

That means less pressure washing. Less streaking. Fewer touch-ups. And longer intervals between maintenance cycles.

We applied our ECOTONE clear photocatalytic coatings to exposed architectural precast concrete elements inside the Anzac Memorial at Hyde Park, to minimise maintenance in a high-traffic urban setting. Even without any change in appearance, the building’s surface remains clean, visually sharp, and resistant to environmental wear.

Another standout is the Sirius building in Sydney. Originally a 1970s public housing complex, the building was transformed into high-end residences while retaining its brutalist character. ECOTONE was initially engaged for colour correction, but the project expanded into a full facade renewal. Our team applied both long-life colour and photocatalytic coatings, ensuring the refreshed concrete surfaces not only matched the design intent but also remained protected from pollution and water ingress for years to come.

The Bigger Picture: Cleaning the Air, Silently

The real strength of photocatalytic coatings is what they do beyond the surface by converting harmful air pollutants like nitrogen oxides (NOx) into harmless, water-soluble nitrates that wash away naturally. In effect, they turn a concrete wall into a passive air purifier.

“1,000m² of treated concrete can remove up to 14kg of NOx annually, which is the equivalent of planting 15 to 20 mature trees in terms of air purification.” – Guerrini, Construction and Building Materials, 2012: NOx-reduction in city tunnel coatings.

This invisible benefit makes a big difference in car-heavy areas, transport corridors, and urban precincts where air quality is under pressure.

Colour by Design and Designed to Stay That Way

Because ECOTONE’s coatings are mineral-based and breathable, they’re ideal for colour-correcting or enhancing aged or mismatched materials. And when paired with a photocatalytic topcoat, those finishes stay brighter, longer.

One project where this invisible benefit becomes visible is at Macquarie University. We were brought in to restore the concrete facade at 18 Wally’s Walk, a key administrative building on campus. We applied our long-life mineral colour coating to correct and unify the weathered concrete tone, followed by a photocatalytic topcoat to reduce surface ageing and contribute to improved air quality on site. The result is a cleaner, brighter building with a performance layer that works all year round, whether it’s rain, hail or shine.

When Performance Meets Aesthetic Freedom

One of the big questions we hear is: Will this limit my colour palette?

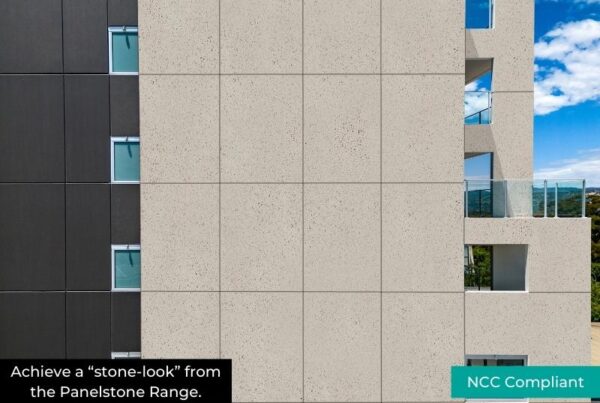

Not at all. Photocatalytic coatings are transparent and breathable, meaning they can be layered over any ECOTONE finish. Whether you’re aiming for bold colour, natural stone tones, or subtle mineral textures, you will still get the performance.

Through our Colour by Design™service, we helped create surfaces that are custom to the architect’s vision, then made self-cleaning using a clear topcoat. This gives the design team complete freedom in colour and texture, with none of the long-term maintenance burden typically associated with lighter finishes.

Prior to applying our photocatalytic coatings, we can also correct any colour imperfections on existing concrete surfaces to match the design intent of the project.

At Crystalbrook Kingsley, Newcastle’s first luxury hotel, ECOTONE’s photocatalytic system was used to preserve and protect the building’s concrete facade. The finish supports the hotel’s sustainability ethos by reducing the need for harsh cleaning chemicals, while maintaining its striking architectural form in a salt-rich coastal environment. The original surface was dirty from coal dust and weathering over time. We cleaned, refreshed the colour to the new design intent with ECOTONE Minsil and then applied self-cleaning coating to keep the fresh new appearance.

Compatible with a Range of Substrates

Photocatalytic coatings are most commonly used on:

- Precast and in-situ concrete

- Clay brick and block

- Mortar and cement render

- Fibre cement sheet

- Internal concrete or masonry walls exposed to daylight

They’re also ideal for public buildings, transport infrastructure, educational institutions, and healthcare environments, where cleanliness, air quality, and lifecycle cost are top priorities.

What This Means for Architects and Builders

Photocatalytic coatings add value on multiple levels:

- Less maintenance – fewer call-backs, less access equipment, lower costs

- Longer-lasting design intent – surfaces stay true to their original appearance

- Better environmental outcomes – air purification, VOC breakdown, pollutant control

- Improved material performance – protects colour, reduces surface degradation

In other words, they help your project perform better, look better, and last longer without affecting your design intent.

A Passive Solution with Active Impact

Photocatalytic coatings aren’t a flashy technology. They don’t hum or glow. But they work quietly, continuously, and with purpose, keeping your building cleaner, your surfaces sharper, and your urban air just that little bit better.

For ECOTONE, this is what good coatings do. They support the building. They serve the people. And they leave less impact on the world around them.

Ready to explore what’s possible?

Talk to our team about making your next concrete facade breathable, self-cleaning, and beautifully designed for the long haul. Whether you’re correcting colour, enhancing texture, or aiming for a high-performance finish, we’ll help you make it last!