Transforming Interior and Exterior Surfaces with Limitless Creativity using Material Finishes

Introduction

In the dynamic world of building and construction, innovation and technology continue to shape the landscape. And among these transformative elements, Material Finishes have emerged as a true game-changer, redefining the aesthetics and functionality of buildings worldwide.

Architects and builders now have the power to unleash their creativity through customised and applied Material Finishes. These finishes bring unprecedented beauty and ingenuity to projects, breathing life into architectural visions.

As pioneers of eco-friendly and sustainable building coatings, we at ECOTONE understand the importance of Material Finishes in tackling architectural challenges with remarkable success. In this blog post, we explore why our clients are turning to Material Finishes, their extraordinary benefits, practical uses, and the future of this revolutionary advancement.

So, what exactly are Material Finishes?

Material Finishes, also known as surface finishes, are the final treatments or coatings applied to building materials. Their purpose is to achieve or enhance desired aesthetics, protection, or functional properties.

The internal surfaces that can be applied to include:

- Fibre cement

- CFC

- Plasterboard

- Internal Linings

The external surfaces that can be applied to include:

- Concrete

- Brick

- Block

- FC Cladding

- CFC Cladding

- GRC

Imagine creating stunning brick appearances on concrete, striking timber finishes on cladding, or the allure of a weathered look on a brand-new facade. With Material Finishes, the possibilities are endless, and the best part is that they can be achieved efficiently and cost-effectively.

Unleashing the Power of Material Finishes with use cases

In an ever-evolving construction industry, Material Finishes play a crucial role in enhancing the beauty, longevity, and environmental sustainability of buildings worldwide. From our experience, our clients rely on these finishes to achieve a range of project goals:

1. Bring vision to life with Aesthetic Versatility:

Different material or finishes offer unparalleled aesthetic versatility, allowing architects and designers to create stunning visual effects and unique designs that elevate the beauty of buildings and interior spaces. By applying different materials with various colours, textures, and materials, architects can achieve striking combinations that reflect the project’s vision and character.

Here are a couple of use cases:

Field St Development: A Masterpiece of Colour and Texture

The Field St Development project is a true testament to the magic we can create. The uncoated Exotec CFC Cladding, adorned in our enchanting ECOTONE Metallic finish, gleams with a golden hue and dramatic black vertical lines, mimicking the rebates of concrete panels.

Lastly, the multi-colour application approach on the grey brick molded precast, using a combination of ECOTONE Minsil and ECOTONE Matt Translucent, perfectly simulates the beauty of natural brickwork.

With our long-life stains, we deliver the WOW factor to the cladding and concrete of the breathtaking Field St.

Carlaw Park Student Village in New Zealand: Redefining Durability and Aesthetics

When Ashton Mitchell Limited, the architects of Carlaw Park Student Village dreamed of a stunning Corten façade system, they faced a dilemma. How could they maintain the aesthetic appeal for years to come without the staining issues? That’s where we stepped in. Through close collaboration and our revolutionary Customer Experience Design (CXD) journey, we developed a system that exceeded their expectations.

We applied the Corten finish to the external precast and also to the internal plasterboard at the stairwells, ensuring a harmonious blend between the inside and outside aesthetics.

Our Material Finishes design provided the plasterboard with a weathered metal Corten finish without the hassle of continual corrosion of the metal and rust falling on below flooring. We think this finish perfectly matches the exterior Corten long-life colour application and adds a touch of elegance to the building’s interior.

This sustainable solution not only saved time and costs, but also delivered panels with remarkable durability and low maintenance requirements. You can dive deeper into this remarkable project here.

- Grey Precast Concrete Coloured with Windows Fitted

- Grey Precast Concrete Coloured with Windows Fitted

- Site Installation

- The Results

- The Results Close Up

2. Revive and Correct with Colour Matching: Give Structures a Fresh Lease on Life

Material Finishes play a vital role in rectifying imperfections, concealing flaws, and reviving the appearance of building surfaces. Whether it’s a new structure that needs to be colour-matched to the rest of the building, or masonry or concrete that needs to be restored, Material Finishes provide a versatile solution. They breathe new life into old structures, ensuring their enduring beauty.

One of the most remarkable examples of masonry staining to existing brickwork is the Campbell House School in Glenfield, New South Wales. The school wanted to restore the beauty of its external brickwork, but there was a persistent problem. A wall mural had left traces of residual paint that did not match the original dry pressed brickwork surrounds. The builder, J Walter Group, contacted us for a colour-matching solution.

Our colour technicians applied ECOTONE Matt on-site, our proprietary masonry staining system. We carefully matched the colour of the stained brickwork with the original brickwork, creating a seamless transition.

The outcome was spectacular. The silhouette from the wall paint was no longer visible, and the brickwork appeared as if it was never touched before.

You can see the colour match here.

- Before

- After

Docklands Primary School also sought our expertise in recolouring precast panels to achieve a more uniform red oxide appearance. Our ECOTONE Minsil and ECOTONE Matt Plus coatings seamlessly blended the patches with the surrounding panels. Additionally, the red oxide precast panels were coloured to restore the desired aesthetic.

- Before

- Before

- After

- After

3. Turn Unsightly buildings into a Work of Art

Gone are the days of dull concrete walls and basic paint finishes. Modern Material Finishes offer a wide range of visually striking options, allowing architects and builders to customise the aesthetics of their work to meet specific project requirements. These finishes can transform buildings into awe-inspiring works of art that satisfy clients’ preferences and needs.

For instance, take a look at our East Palm Beach Apartments project. After a mishap with a scaffold on a 10-story residential project with a precast facade, the builders at McNab Constructions were left with an unsightly finish. We came to their rescue by restoring the fair-faced concrete appearance, using innovative concrete surface stains applied via rope access. The result was flawlessly beautiful concrete walling, soffits, and foyer.

With our Material Finishes, you have endless possibilities to customise the aesthetics of your project. From home extensions to brickwork infills, our custom finishes not only evoke emotions but also set the perfect mood.

- Before

- After

4. Sustainability Goals: Eco-Friendly Solutions for the Construction Industry

In today’s world, sustainability is at the forefront of the construction industry. We’re thrilled to be part of this important movement towards providing more environmentally friendly solutions.

One proven approach to sustainability in construction is the use of Material Finishes. By revitalising existing materials and structures, they minimise the need for new construction and the depletion of natural resources. Sustainable Material Finishes also enhance energy efficiency and feature coatings made from eco-friendly and low VOC materials. High-quality Material Finishes can also extend the lifespan of building components and surfaces, leading to lower maintenance and replacement needs, reducing waste generation and lifecycle costs.

One successful example of using sustainable Material Finishes is the Crystalbrook Kingsley project, where we developed a top-notch coating system to maintain the restored heritage-listed Kingsley building’s surface appearance. The ECOCLEAN coating system was utilised, which incorporates self-cleaning technology. The Kingsley is a luxury hotel in Newcastle that has received two Asia-Pacific Hotel of the Year awards. By implementing photocatalyst coatings, the project was able to preserve the building’s appearance while reducing maintenance costs.

- Photo credit to Crystalbrook Kingsley

At ECOTONE coatings, sustainability is our priority. Our Material Finishes and coatings are eco-friendly, eliminating the need for rendering and painting entire structures and conserving resources. We prioritise the reuse of ordinary materials and transforming it to look like another. For example, we can make ordinary materials like grey cement render look like authentic sandstone. We can make smooth or timber moulded grey cladding and concrete look like authentic wood.

Our protective and functional finishes also shield buildings from UV radiation, moisture, and pollutants, minimising wear and tear and lowering maintenance requirements.

By collaborating with architects and builders, we can all contribute to a greener and more environmentally conscious future in the construction industry.

The Exciting Future of Material Finishes in Prefabricated and Modular Construction

Step into a world where technological advancements collide with architectural innovation. The future of Material Finishes is brimming with potential in the realm of prefabricated and modular construction. Imagine achieving high-end aesthetics while keeping costs under control. It’s not just a dream – it’s a reality.

Let’s delve into some real-life examples of building projects that epitomise the power of Material Finishes in the realm of prefabrication and modular construction.

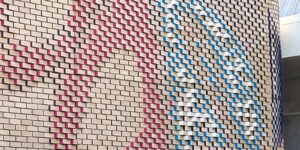

Central Train Station in Australia sets the stage for what’s possible. Our talented NSW colour technicians utilised ECOTONE Sharp to achieve a stunning coloured glazed brick look. Through our prefabricated façade service and in collaboration with PGH Bricks and Pavers and Waeger Constructions, the station’s feature brickwork, designed by artist Bronwyn Bancroft, comes to life. The precast elements feature vivid coloured ends, creating a captivating transitioning artwork as trains come and go.

By choosing ECOTONE to colour the brick ends before installation, our client was able to significantly reduce waste, project time, energy consumption, and the need for costly on-site scaffolding. This is just one example among others as mentioned above, where Material Finishes have elevated the world of prefabrication and modular construction.

- Central Station

- Central Station

- Central Station – Close Up

- Central Station – Close Up

In New Zealand Eden View Apartments is another inspiring example where we ultised ECOTONE Matt and ECOTONE Sharp to create a range of tones that perfectly replicate natural brickwork on grey brick molded precast concrete. Our team completed the application at the Concretec precast yard, ensuring a flawless finish once installed on-site.

- Eden View Apartments

- Eden View Apartments Close Up

All ECOTONE colours were individually customised in collaboration with each client to ensure a realistic aesthetic that aligns with the architect’s vision.

With modular construction methods, Material Finishes can be expertly applied off-site, guaranteeing exceptional quality control and allowing for faster assembly on-site. The result? Project timelines are accelerated, savings on programme and scaffold costs and boundless opportunities for creative expression and design flexibility are opened.

Across Europe, sustainable construction practices are taking center stage, with Material Finishes leading the charge. From eco-friendly coatings to innovative recycled materials, architects and builders are embracing these revolutionary finishes to minimise environmental impact and enhance energy efficiency in prefabricated structures.

Conclusion

Material Finishes are revolutionising the construction industry, igniting a wave of transformation. They flow across interior plasterboard, insitu concrete, precast, fibre cement, compressed fibre cement. These innovative finishes have the power to evoke emotions and embody a building’s unique identity, turning every project into a breathtaking work of art.

As technology advances, Material Finishes will play an increasingly vital role in overcoming project challenges and propelling the industry towards a future focused on prefabricated and modular construction. Not to mention the sustainability benefits that perfectly align with the growing demand for eco-friendly solutions.

Unleash the power of Material Finishes with ECOTONE

At ECOTONE coatings, we are proud to lead the way in Material Finishes. Our passion lies in empowering architects and builders to create sustainable and visually stunning buildings that will define our urban landscape for generations to come. From breathtaking brick appearances on concrete to striking timber finishes on cladding, we can turn your wildest design dreams into a reality. Our mesmerising interior and exterior surfaces redefine architectural brilliance.

With our cutting-edge Customer Experience Design (CXD), we work hand in hand with architects and builders to offer customised Material Finishes, opening a world of possibilities to meet your project goals. Our team of experts will guide you in creating captivating, sustainable, and innovative buildings that leave a lasting impact.

Join us on a transformative journey where creativity knows no bounds and architectural brilliance becomes a reality.